Products

18 Years Factory Ricoh Toner Powder - TN812 Black Toner Cartridge A8H5050 A8H5030 for Konica Minolta Bizhub 758 808 – JCT

18 Years Factory Ricoh Toner Powder - TN812 Black Toner Cartridge A8H5050 A8H5030 for Konica Minolta Bizhub 758 808 – JCT Detail:

Quick Details

| Type | Compatible Toner Cartridge |

| Compatible Model | Konica Minolta |

| Brand Name | Custom / Neutral |

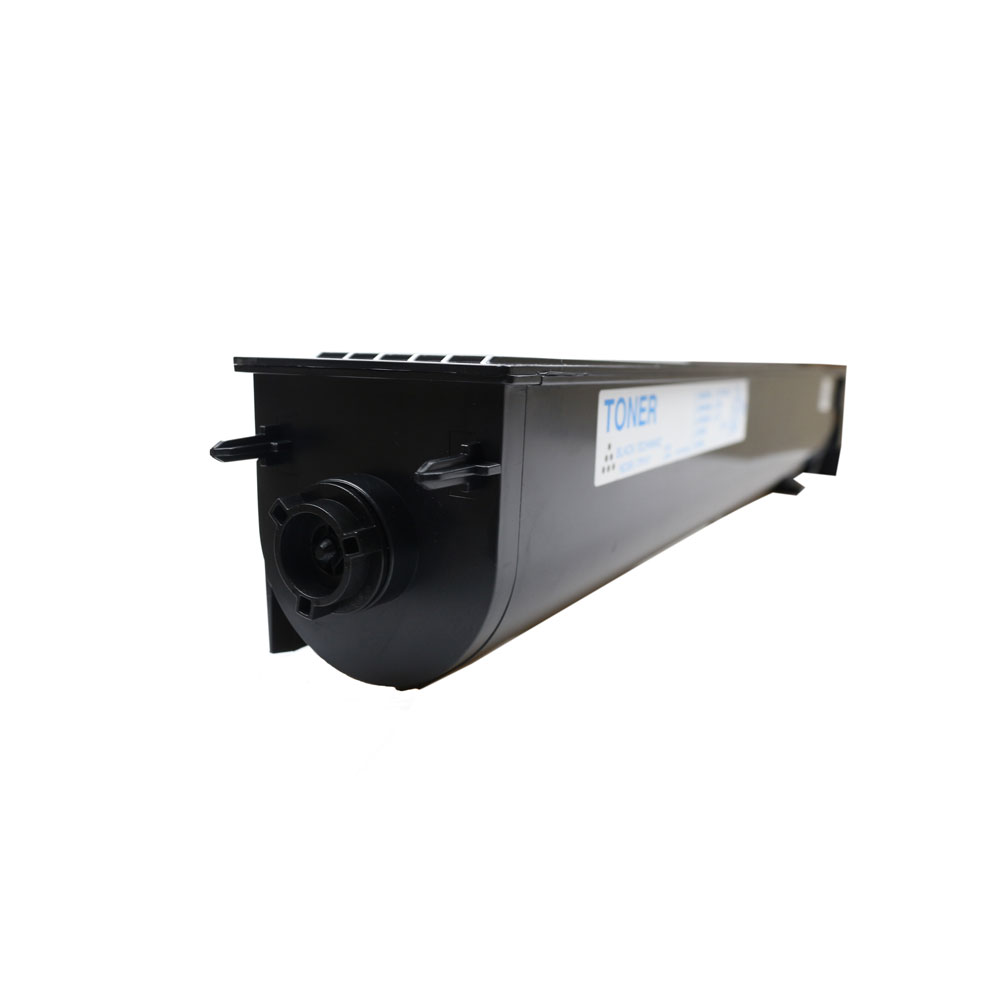

| Model Number | TN812 |

| Color | BK only |

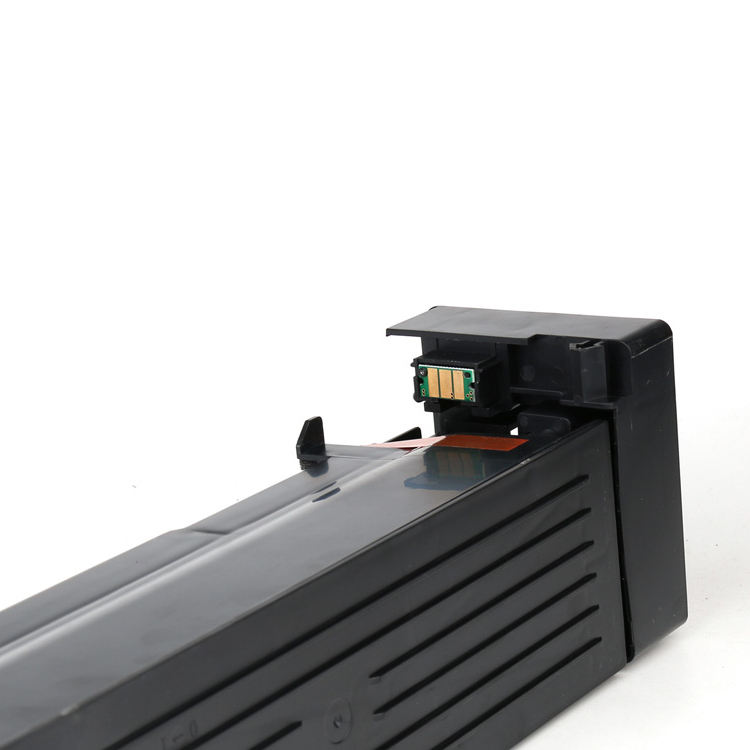

| CHIP | TN-812 has inserted a chip |

| For use in | Konica Minolta Bizhub C3350i C4050i |

| Page Yield | Bk:40,800(A4, 5%) |

| Packaging | Neutral Packing Box (Customization Support) |

| Payment method | T/T bank transfer, Western Union |

→ If you are interested in our products, send us inquiry for more details.

Compatible Printers

For Konica Minolta Bizhub 758

For Konica Minolta Bizhub 808

100% Satisfaction Guarantee

● Compatible products are produce with quality New & Recycled components in ISO9001/14001 certified factories

● Compatible products have a 12 months performance guarantee

● Genuine/OEM Products have a one year manufacturer warranty

Basic introduction of toner cartridge

1. Photosensitive drum: The photosensitive drum is the heart of the integrated toner cartridge. All other components are distributed around the photosensitive drum and play different roles around the drum. In the imaging process, the photoreceptor drum is charged and irradiated by the laser, and the electrostatic latent image is formed on the surface to further form a visible toner image.

What is the toner cartridge

2. Magnetic roller: that is, the developing roller, which is one of the components that have the greatest impact on image density. It is responsible for sucking the toner out of the toner bin and rubbing it with the toner to charge the toner. The charged toner “jumps” due to the development bias voltage on the magnetic roller.

3. Powder scraper: installed under the magnetic rod, the powder scraper is responsible for controlling the thickness of the carbon powder layer adsorbed on the magnetic roller and charging the auxiliary carbon powder through friction.

4. Powder bin: the so-called powder bin is the warehouse for storing toner. Some powder silos have agitators to ensure smooth supply of toner.

5. Waste powder warehouse: the warehouse where waste powder is stored. The toner image formed on the surface of the photoreceptor drum cannot be 100% transferred to the print medium, and part of it will remain on the surface of the photoreceptor drum. Before the next image is formed, it will be scraped by the cleaning scraper and collected in the waste powder bin.

What is the toner cartridge

6. Cleaning scraper: It is responsible for removing the residual toner on the photo drum after image transfer.

7. Conductive rod: there is a carbon powder sensing rod at the outlet of the powder bin of some cartridges, such as C3900A/C4092A, to sense the carbon leakage. When the toner is insufficient and there is a gap between the magnetic roller and the conductive rod, the machine will display that the toner is used up and the TONERLOW signal will appear.

8. Charging roller: charge and discharge the photoreceptor drum.

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of 18 Years Factory Ricoh Toner Powder - TN812 Black Toner Cartridge A8H5050 A8H5030 for Konica Minolta Bizhub 758 808 – JCT , The product will supply to all over the world, such as: Nepal, Hyderabad, Niger, Create Values,Serving Customer! is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly