Products

Factory wholesale Laser Printer Imaging Drum - Konica Minolta DR512 Drum Cartridge Remanufactured A2XN0RD A2XN0TD – JCT

Factory wholesale Laser Printer Imaging Drum - Konica Minolta DR512 Drum Cartridge Remanufactured A2XN0RD A2XN0TD – JCT Detail:

Quick Details

| Type | Remanufactured/New Drum unit |

| Compatible Model | Konica Minolta |

| Brand Name | Custom / Neutral |

| Model Number | DR512 |

| Color | BK C M Y |

| CHIP | DR512 has inserted a chip |

| For use in | Konica Konica MinoltaBizhubC221/C221S/C224/C284/C364/C454/C554 |

| Page Yield | CMYK:100,000(A4, 5%) |

| Packaging | Neutral Packing Box (Customization Support) |

| Payment method | T/T bank transfer, Western Union |

→ If you are interested in our products, send us inquiry for more details.

Compatible Printers

For Konica Minolta Bizhub C221

For Konica Minolta Bizhub C221S

For Konica Minolta Bizhub C224

For Konica Minolta Bizhub C284

For Konica Minolta Bizhub C364

For Konica Minolta Bizhub C454

For Konica Minolta Bizhub C554

For Konica Minolta Bizhub C7122

For Konica Minolta Bizhub C7128

Why Choose JCT?

JCT adheres to the business purpose of “Quality & Customer First”. Most of our raw material are imported from source suppliers in Korea and Japan.We believe that the high quality and the competitive price of our products will help your business development.

JCT has always been committed to solving printing problems for customers, providing customers with high-quality and reasonably priced compatible toner cartridge, greatly reducing the printing costs of our customers.

Very happy with the product and responsiveness to update requests about shipping.

Gostei muito do produto. foi muito rápido e pretendo comprar mais regularmente

Excelente calidad de productos, la atención al clientes es increíble, todo llego en perfecto estado, Gracias

Why Choose JCT?

If the automatic cleaning method fails, it proves that the blockage is serious, usually because the printer has not been used for a long time or the power has been cut off during use, and the nozzle has not been reset. It is a cleaning method to save ink by pointing the syringe at the nozzle, constantly pulling the pressure device, allowing high-speed air flow to clean the nozzle and suck out the remaining ink.

If the above manual cleaning method fails, prepare to disassemble the printer for the following operations. Turn off the power first, unplug the plug, and completely disconnect the power. Remove the moving shaft and rotating belt, carefully pick up the print head, and rinse it with distilled water. Then a jet system is composed of a syringe and a soft rubber tube, which is inserted into the ink inlet hole for cleaning. Be very careful in both steps. Never let water touch the circuit board. If the circuit board gets wet unfortunately, it should be dried immediately with a hair dryer. Finally, install it back into the printer, and execute the software cleaning program again to let the ink wash away the distilled water in the nozzle.

The integrated print head, which has been put aside for a long time, may block the orifice due to the drying of the ink, and can be cleaned after soaking in hot water. Pay attention to the following points when cleaning the print head: a. Do not clean the nozzle with sharp objects, do not hit the nozzle, and do not touch the nozzle with your hands; b. Do not disassemble or install the printing head in the charged state, and do not touch the electrical contact of the printing trolley with hands or other objects; c. Do not remove the nozzle from the printer and place it separately, or place it in a dusty place.

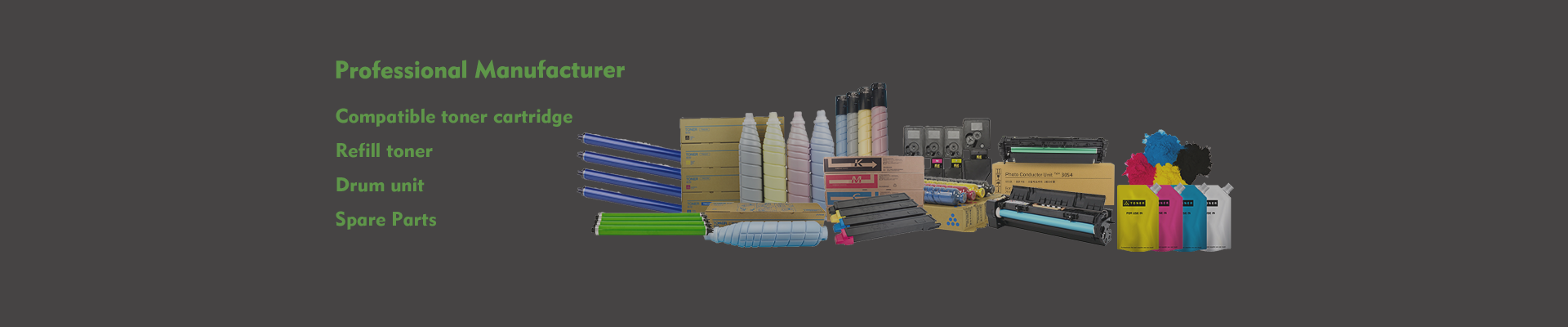

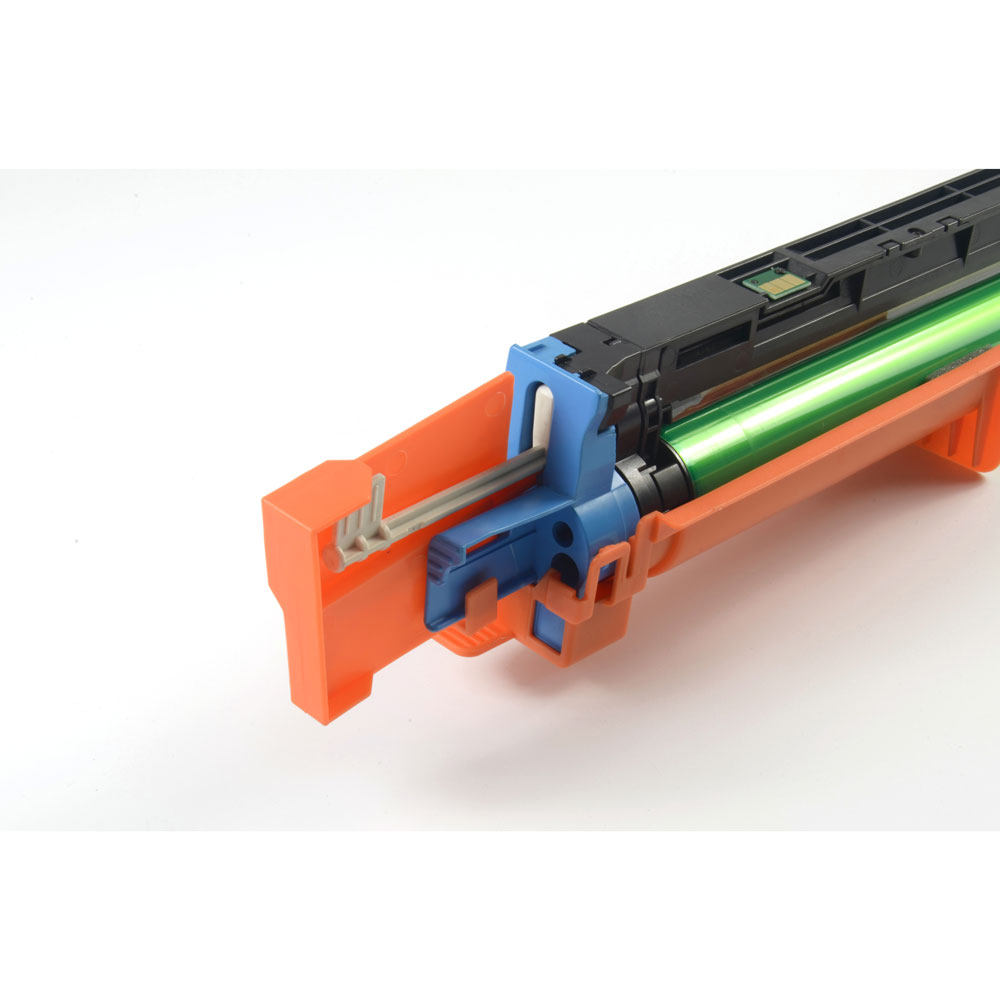

Product detail pictures:

Related Product Guide:

Quality to start with, Honesty as base, Sincere company and mutual profit is our idea, as a way to build constantly and pursue the excellence for Factory wholesale Laser Printer Imaging Drum - Konica Minolta DR512 Drum Cartridge Remanufactured A2XN0RD A2XN0TD – JCT , The product will supply to all over the world, such as: Switzerland, Sierra Leone, Lahore, In order to carry out our goal of customer first and mutual benefit in the cooperation, we establish a professional engineering team and a sales team to supply whole heartedly service to satisfy our customers' requirements. Welcome you to cooperate with us and join us. We are your nice choice.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.