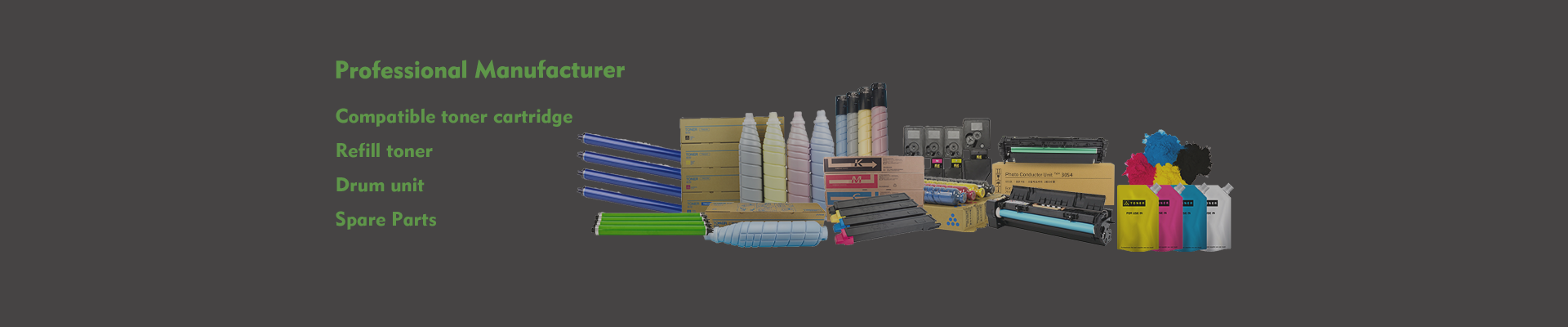

Products

Manufactur standard Black Toner Ink - For Utax CD1025 For Utax CD1030 For Utax CD1040 For Utax CD1035 For Utax CD1050 – JCT

Manufactur standard Black Toner Ink - For Utax CD1025 For Utax CD1030 For Utax CD1040 For Utax CD1035 For Utax CD1050 – JCT Detail:

Quick Details

| Type | Compatible Toner Cartridge |

| Compatible Model | Olivetti |

| Brand Name | Custom / Neutral |

| Model Number | B1179 B1180 B1181 B1182 |

| Color | BK C M Y |

| CHIP | B1179 has inserted the chip |

| For use in | Olivetti D-ColorP2130/MF3003/MF3004 |

| Page Yield | Bk: 7,000(A4, 5%) , Color: 5,000(A4, 5%) |

| Packaging | Neutral Packing Box (Customization Support) |

| Payment method | T/T bank transfer, Western Union |

→ If you are interested in our products, send us inquiry for more details.

Compatible Printers

For Olivetti D-Color P2130

For Olivetti D-Color MF3003

For Olivetti D-Color MF3004

100% Satisfaction Guarantee

● Compatible products are produce with quality New & Recycled components in ISO9001/14001 certified factories

● Compatible products have a 12 months performance guarantee

● Genuine/OEM Products have a one year manufacturer warranty

What are the main steps in the printing process of the laser printer?

Charging: A shielded corona wire is set near the photosensitive drum. When the photosensitive drum starts to rotate, the high-voltage power supply adds several kilovolts of high-voltage to it, and the corona wire starts to corona discharge. At this time, the non-conductive air around the corona wire is ionized and becomes a conductive conductor, so that the surface of the photosensitive drum is charged with positive (negative) charges.

Photosensitivity: when the laser beam irradiates the surface of the charged photosensitive drum, the place where the drum surface is illuminated (i.e., where there are words or images) becomes a good conductor, and the charge flows to the ground, that is, the charge in the illuminated place disappears; Places other than words or images are not irradiated by laser and still retain electric charge; In this way, an invisible electronic latent image of words or images is formed on the surface of the drum.

Development: Development is also “imaging”, that is, “coloring” the electronic latent image with carriers and colorants (single component or dual component toner). The toner is charged. Due to the effect of static electricity, the toner will be adsorbed on the electronic latent image area on the surface of the photosensitive drum, making the electronic latent image become a visible image.

Transfer printing: The principle of transfer printing is also electrostatic induction. The transfer electrode makes the paper have a charge opposite to the polarity of the toner image. When the paper passes through the transfer roller, the developed image will be transferred to the paper.

Fixing: Fixing is the process of fixing an image. When the image is transferred from the photosensitive drum to the paper, it is adsorbed on the paper and is not fixed. When the paper passes between the fixing roller and the pressure roller, it is dried by the heating electrode in the fixing roller and squeezed by the pressure roller, which makes the toner melt and penetrate into the paper fiber, forming a permanent record.

Shading elimination: In the process of transfer printing, when the toner is transferred from the surface of the drum to the paper, there will be some toner left on the drum surface. In order to eliminate the residual toner, a discharge bulb is installed under the paper to eliminate the charge on the surface of the drum, so as to further thoroughly clean the residual toner.

Product detail pictures:

Related Product Guide:

Control the standard by the details, show the power by quality. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Manufactur standard Black Toner Ink - For Utax CD1025 For Utax CD1030 For Utax CD1040 For Utax CD1035 For Utax CD1050 – JCT , The product will supply to all over the world, such as: Chile, America, Roman, We are proud to supply our products and solutions to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.